It is your legal responsibility as an employer and manufacturer to understand how safety data sheets are used to assist your workers to operate in a safe and healthy workplace.

This article will provide you with a thorough understanding of SDS, whether you’re new to safety and compliance or working with hazardous chemicals.

What Is A Safety Data Sheet?

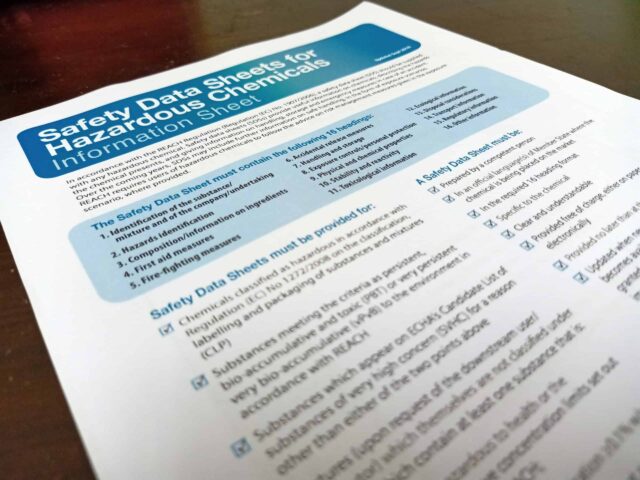

A Safety Data Sheet (previously known as a Material Safety Data Sheet) is a comprehensive informational document created by a hazardous chemical producer or importer. It is a description of the product’s physical and chemical characteristics. Toxicity, flash point, spill and leak procedures, storage requirements, and exposure control are all included in the SDSs.

Check this blog for professional SDS services to help you ease your workload.

Safety Data Sheets: What Are They Good For?

A safety data sheet is typically used to gather information regarding dangers, including environmental threats, as well as advise on safety procedures. It’s crucial to note that SDS is more concerned with products than with individual workplaces.

Yet, an SDS allows an employer to build an active program of workplace-specific worker protection measures and training, as well as to consider environmental protection measures. Emergency responders, poison centers, transportation businesses that transit hazardous chemicals, and professionals and consumers who use pesticides benefit from safety data sheets.

When a safety data sheet is created, the professional responsible must meet several conditions. In other words, an SDS is required when substances and mixtures meet the GHS’s harmonized criteria for physical, chemical, or environmental hazards.

A substance is hazardous when it contains carcinogenic ingredients, harmful to reproduction, or is toxic enough to exceed SDS limits set by the criteria for specific compounds. Different agencies may also need a safety data sheet for mixes that do not match categorization standards but contain hazardous substances in particular concentrations.

SDS Is Essential For Chemical Manufacturers

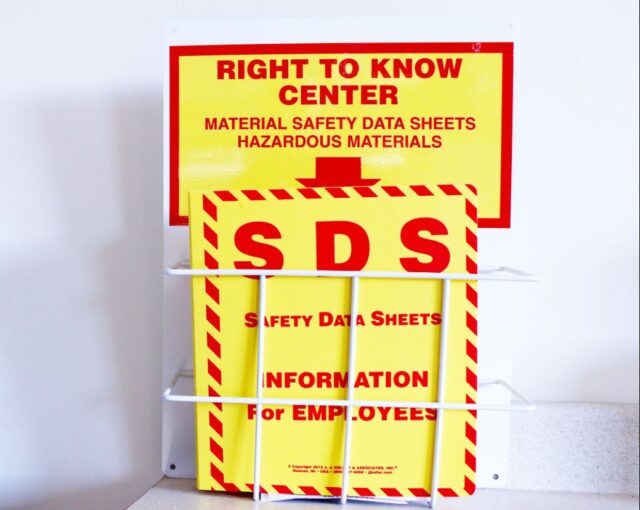

According to the SDS standard, workers have a right to know what hazards are linked with the substances they use in the workplace. This guideline must be followed by chemical makers and employers who have chemicals in their workplace, as OSHA is the most frequently reported violation. You might be charged $70,000 in fines per infraction.

SDS information helps employees choose safe products and prepares them to respond appropriately to exposure and emergency circumstances.

Format and Content of a Safety Data Sheet

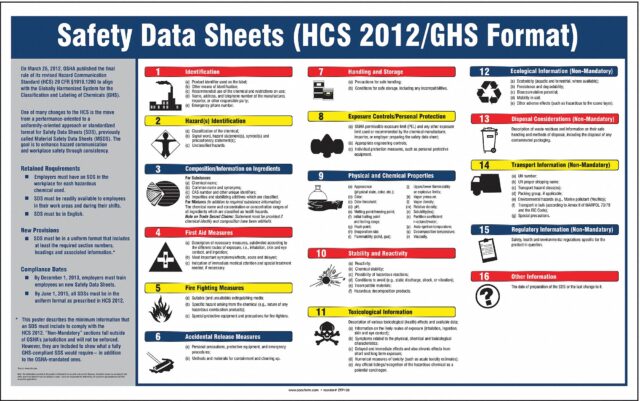

There are 16 parts on the safety data sheet. There should be no changes to the format. The following are the sections:

- Identification- Identifies the substances on the SDS and their suggested applications, as well as the supplier’s contact information.

- Hazard(s) identification – Determines the chemical’s risks as well as the relevant warning information.

- Ingredient composition/information — Identifies the ingredient(s) in the product, including any contaminants or stabilizers.

- First-aid measures — Describe the primary care that untrained responders should give to someone who has been exposed to a chemical.

- Fire-fighting procedures — Entails steps for putting out a chemical-caused fire.

- Accidental measures- Measures to prevent or reduce exposure to people, places, and the environment in the case of an accidental release — Make suggestions on how to respond to spills, leaks, or releases, including containment and cleanup procedures.

- Handling and storage – Provides instructions on how to handle and store items safely.

- Exposure limits, engineering controls, and personal protective measures — Identifies the exposure limits, engineering controls, and personal protective measures to utilize to reduce exposures.

- Physical and chemical properties- Identifies a compound’s physical and chemical properties.

- Stability- Describes the chemical’s reactivity dangers and stability.

- Toxicology- Provides toxicological and health consequences information or indicates if data is unavailable.

- Ecological data – Provides data to assess the chemical’s environmental impact before deciding whether or not to release it into the environment.

- Disposal- Provides instructions on proper disposal, recycling, or returning the chemical to its original container, as well as safe handling techniques.

- Transport- Provides categorization information for shipping and transporting hazardous substances by road, air, rail, or sea.

- Regulatory information — Determines the product’s unique safety, health, and environmental requirements that are not listed elsewhere on the SDS.

- Other information — Includes the date the SDS was created and the most recent date on which it was last revised.

Remember that the safety data sheet should have at least minimal information for each part and should provide clear information. If a particular piece of information isn’t appropriate or available, make that clear on the SDS. It’s also crucial to understand whether subheadings or extra information are required for national or regional areas and incorporate that information.

Who Should Have SDSs?

The following stakeholders require the use of SDSs:

- Employees who may be exposed to a chemical hazard on the job

- Employers need to know about proper storage, usage, and precautions while using a chemical compound.

- Firefighters, hazardous material crews, emergency medical technicians, and emergency department employees are examples of emergency responders who require an SDS during an emergency.

SDSs are not intended for the general public. The hazards of working with the material in an occupational setting are reflected in an SDS. An SDS for paint, for example, is not as significant to someone who uses a can of paint once a year as it is to someone who uses it 40 hours a week.

What Is the Difference Between SDS and MSDS?

OSHA HCS required material safety data sheets (MSDS) for hazardous substances in the workplace prior to GHS alignment. Safety data sheets have replaced OSHA HCS requirements following GHS alignment.

The way information is presented on MSDS and SDS sheets differ significantly. Both documents include information on the dangers of chemical compounds and prevention steps to undertake when working with hazardous materials. However, SDS sheets represent information following GHS alignment guidelines for a safer workplace.

Conclusion

Chemical exposure can cause a wide range of diseases and illnesses, from burns and rashes to nervous system and organ damage, as well as cancer. When dealing with, transporting, or disposing of hazardous chemicals, understanding every part of the SDS can protect personnel and workspaces from potential hazards.