The modern wrapping industry offers flexible covers as the most demanded and advanced way to pack and store products. Its high demand is explained by a wide selection of options for any kind of goods.

This type of cover is welcome in multiple industries, including food, household goods, cosmetic products, etc. Thus, we provide a precise flexible packaging industry overview below.

In their turn, modern consumers set high demands for covers and prefer to purchase products wrapped in accordance with standards. In such cases, they are sure of product quality and freshness.

They believe that quality packaging can preserve integrity, shape, nutritional properties, and color. And it is true. Thus, flexible covers fully meet this demand since they feature the ability to re-open, carry, and preserve physical properties.

Let’s list some statistics that say in favor of the popularity of flexible wrappers:

- enterprises spend over $1 trillion annually on the manufacturing of wrappers;

- flexible packages take up about 40% of the global wrapping industry;

- 62% of customers give preference to flexible covers because of their convenience, customization, and versatility.

Here are the main reasons why modern enterprises shift to using flexible containers for packing their products.

If you need flexible solutions for your business, visit the website Uniflex for ordering flexible packaging manufacturing. Uniflex is a reputable company that provides modern solutions and guarantees high-quality results for its clients.

The Manufacturing Process

First, let’s highlight the features of the flexible packaging manufacturing process. The production process starts with selecting suitable materials for wrappers. Depending on the type of covered goods, multiple options exist.

Materials for Flexible Wrapper Manufacturing

- LDPE (low-density polyethylene) and LLDPE (linear one) are types of plastics, where the volume is bigger than the mass. It features high resistance to moisture, chemical impacts, and shocks. The material is sustainable since containers are recycled well.

- PET, PETE (Polyethylene Terephthalate) is a lightweight, transparent, and elastic material. Yet, it is still very durable ad resistant to tear. Eco-friendliness is explained by excellent recycling properties. Recycled parts are used for the production of geotextile.

- PP (Polypropylene) features perfect resistance to extreme (high) temperatures and chemicals. Thus, containers are used to pack and store hot products and chemicals/medicines.

- PVC, Vinyl (Polyvinyl Chloride) is used for the production of rigid containers since the material keeps shape perfectly. Vinyl is popular in non-food industries. Yet, the material is replaced by greener alternatives.

- POF (Polyolefin) is tear-resistant and durable, which is approved by FDA. Thus, the material is popular in the food industry as a provably safe for humans.

- HDPE (High-Density Polyethylene) is manufactured from crude oil. It is safe for humans. which is why it is used in multiple industries (both food and non-food). HDPE containers are characterized by resistance to environmental influences, density, and customization.

The Specificity of Flexible Cover Technology

Now, let’s point out the main stages of the flexible packaging production process:

- The selection of a suitable material.

- Shaping using multiple methods, including thermoforming or injection.

- Decoration with logos, images, and other marking info.

- Packing goods.

- Distributing on the market and sales.

- Consumption. Customers can use containers multiple times.

- Waste sorting and recycling.

Types of Flexible Packages

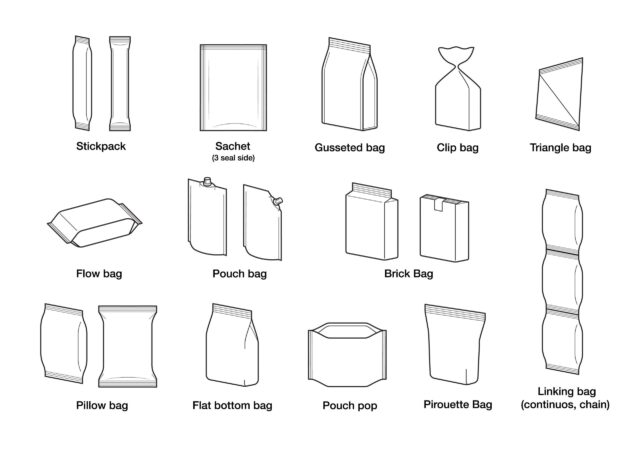

The following types of wrappers are found on the market:

- Sample Pouches are one- or multi-layer covers made of film or foil and sealed under high temperatures. They are usually pre-formed and ready to use.

- Printed Pouches are classic sample covers, to which all the marketing info is applied.

- Sachets are single-use bags usually made of paper or cupboard. Brands widely used them during trade shows to distribute samples of the products.

- Printed Roll Stock is a long unformed roll of covers manufactured specifically for the demands of enterprises and supplied to co-packers, where it is formed, sealed, and applied to products.

- Stock Bags are standard transparent plastic bags, on which marketing info is printed.

Pros of Flexible Covers

This type of wrapper has the following benefits:

- Less material is used for its production if compared to other types of containers.

- Space-saving since flexible packages are more compact, which means that they occupy less space during transportation and storage on store shelves. This benefit entails saving costs on logistics.

- Perfect resistance to moisture, sunlight, humidity, etc. Covers protect products from the negative impact of the environment and preserve freshness and integrity.

- Customizable designs due to the ability to use multiple printing techniques to promote goods.

- Sustainability since most types of plastics used for flexible wrapper production are recyclable.

Applications and Industries Using Flexible Packaging

Flexible packaging is widely used across diverse applications and industries due to its versatility, convenience, and effective product preservation. Here are some key industries and applications that extensively rely on flexible packaging:

Food and Beverage Packaging – The food and beverage industry heavily utilizes flexible packaging for snacks, confectionery, dairy products, beverages, and frozen foods. It provides exceptional barrier properties, preserving product freshness, safeguarding against moisture, and extending shelf life.

Pharmaceutical and Medical Packaging – Flexible packaging plays a vital role in pharmaceuticals and medical sectors for packaging medications, medical devices, and healthcare products. It ensures product integrity, protects against contamination, and often incorporates features like child-resistant closures and tamper-evident seals.

Personal Care and Cosmetics Packaging – The personal care and cosmetics industry extensively employs flexible packaging for shampoos, lotions, creams, makeup, and perfumes. This packaging offers aesthetic appeal, easy dispensing, and shields against light and air exposure.

Household Products Packaging – Flexible packaging finds wide application in packaging household items like cleaning agents, detergents, wipes, and air fresheners. It ensures product safety, convenient storage, and ease of use.

Pet Food and Animal Feed Packaging – The pet food and animal feed industry rely on flexible packaging to maintain freshness and nutritional value. It effectively protects against moisture, pests, and oxygen, ensuring high-quality products.

Industrial and Chemical Packaging – Flexible packaging is employed for packaging industrial products such as chemicals, lubricants, fertilizers, and paints. It facilitates safe storage, transportation, and easy handling.

Now, you know what flexible packaging is and how is it manufactured. The industry offers versatile solutions for all sorts of enterprises. Flexible packages are convenient for use and safe; moreover, customers are loyal to such covers.