Modern production today could not function without new technologies. This is also the case when it comes to products and semi-products that need finishing. Many of these works require cutting, which is done today with modern laser technology. This tech involves cutting the material with the help of a laser beam aided by the action of inert gas. Today, this technology is widespread and necessary for the functioning of many industries.

However, like any other – laser cutting technology has some drawbacks. Therefore, we will tell you about some advantages and disadvantages of laser cutting machines.

Basic Rules Of Laser Cutting

Laser technology is widely used today – and can be used in the processing of various materials, most often metals. Therefore, we can say that this technology is used for various cuttings – ranging from cutting hard metals such as stainless steel to soft ones, such as aluminum.

One of the reasons for the mass use of this technology is the fact that today it is the most economical cutting option that is becoming more advanced. Through various types of improvements in laser technology – the quality, as well as the economy of cutting materials, are improved. Today, we know the three basic methods of laser cutting. These are melting laser cutting, oxygen laser cutting, and evaporation laser cutting.

3 Simple Ways: Laser Cutting Machines Adjustment

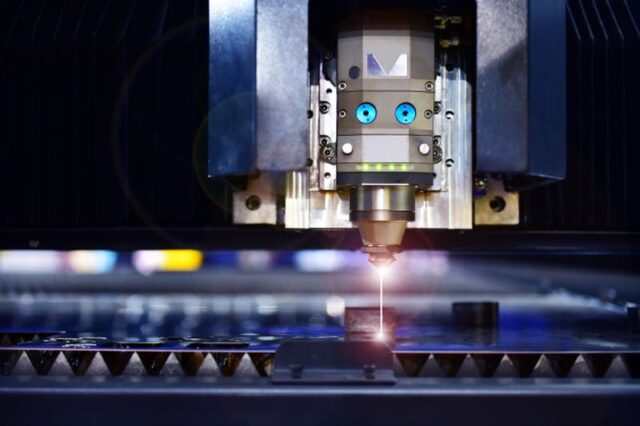

Today, for laser cutting of materials – we use technologically advanced machines with customized work. Before starting the cutting process, it is necessary to adjust the machine parameters – to make laser cutting as efficient and economical as possible. Since all industrial lasers are powered by CNC technology, the adjustment is very simple. The cutting operator must adjust the movement of the laser cutter head, the movement of the metal, or other material to be cut. Also, it is necessary to adjust the mixed movement if necessary.

In practice, metal motion and mixed motion are denoted by the letters X and Y, while laser head motion is denoted by the letter Z. Each of the mentioned modes of operation has its benefits and faults. Along with the cutting process, which takes place by moving the material to be cut, the laser head is stationary. Mixed motion, on the other hand, is a combination of the motion of the laser head and the piece being cut. Finally, moving the laser head is the last type of cutting in which the piece being cut is stationary and the laser head is moving. This type of cutting is also the fastest.

Modern Technology Of Laser Cutting

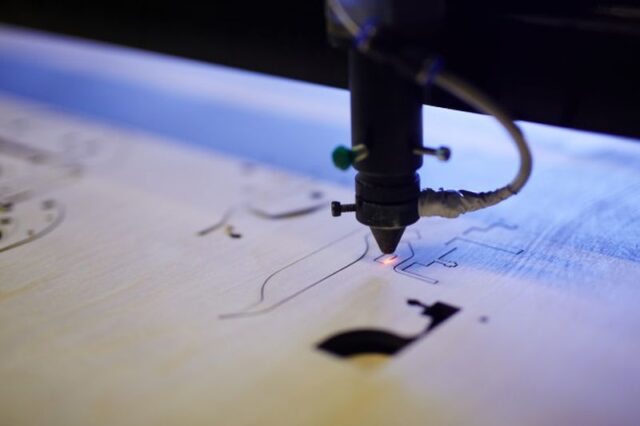

The technology of laser cutting of materials is considered today one of the most economical and available in the material processing industry. This technology is also very precise, so with good maintenance and proper optimization of machines – it will give high-quality results. Although this technology is most commonly used when cutting metal surfaces – it can also be used to cut other materials.

In addition to metal, it is most commonly used for cutting glass surfaces, various plastic materials, wood, etc. However, like many other technologies, the laser cutting procedures must be viewed from all sides. Although it has many advantages – it also has certain disadvantages. Somewhere we will use it as a primary cutting technique – while in other cases, it will serve as an alternative. The question is, what are the advantages and disadvantages of this material processing technology?

4 Pros And Cons Of Laser Cutting Machinery

1. Extreme Precision And High-Quality

One of the principles of this cutting technology is the high accuracy and nature, that is, the high-quality of the cut material. With the advancement of CNC innovation and the improvement of the laser shaper head – the accuracy is much better. Besides high accuracy, the benefit is also connected to the cutting time, which is progressively abbreviated.

2. Free Space Between The Material And The Machine

Besides working fast and extremely precise, one of the fundamental advantages of such machines – is that we can avoid the contact between the slicing device and the surface that we want to be cut. According to the ways of cutting, but also with the materials that are cut – we can distinguish different types of laser cutters. Today we can find various models of machines – from the most basic ones to some new and improved versions such as acrylic co2 laser cutting machine.

According to companies such as elephant-cnc.com – with less improved machine cutting methods – a major issue is a temperature, which will usually have an impact and harm the surface that we want to cut. It is happening because of the gas used in this process and the previously mentioned things – this issue is nearly non-existent in this cutting method.

3. Energy

The main disadvantage of laser cutting is the power, i.e., energy that is needed to create a laser beam. However, as laser technology is evolving and constantly improving, this shortcoming should very likely be corrected soon.

4. Evaporating

This is certainly one of the fundamental flaws of this technical procedure. The evaporation will most often take place when cutting materials like plastic. However, there are ways to take out this weakness. Therefore, professionals, in some cases, use a few distinct arrangements available that are as of now generally costly and complex to actualize.

Additionally, one of the issues of laser cutting is the upkeep of the delicate segments of the laser head. During upkeep, there is likewise a danger of conceivable injury to the specialist, who can be harmed by the laser pillar whenever taken care of imprudently.

Conclusion

The importance of this type of technology and machines in the industry today is immeasurable. Not only does it help us to do things flatteringly, but it also saves us time and, ultimately, money. Most of the machines utilized for laser processing adopt CNC control.

Due to the fact that 2D and 3D technologies of cutting are a very sophisticated way of machining, their utilization is widespread. Laser devices are utilized in the car body processing, in the aerospace industry and also cutting special materials like titanium, aluminum, chrome, etc. Laser cutting machines are also used to process non-metals, which will increase the further use of this technology.